Part 6: Combining Executive Life, Project Development & Construction

I think every person has multiple facets to their personality. I have known that since my younger years, I have been a car guy. I love mechanical & technical things, construction, building things whether physical or in abstract forms. I love to draw, to work with wood, to operate big equipment.

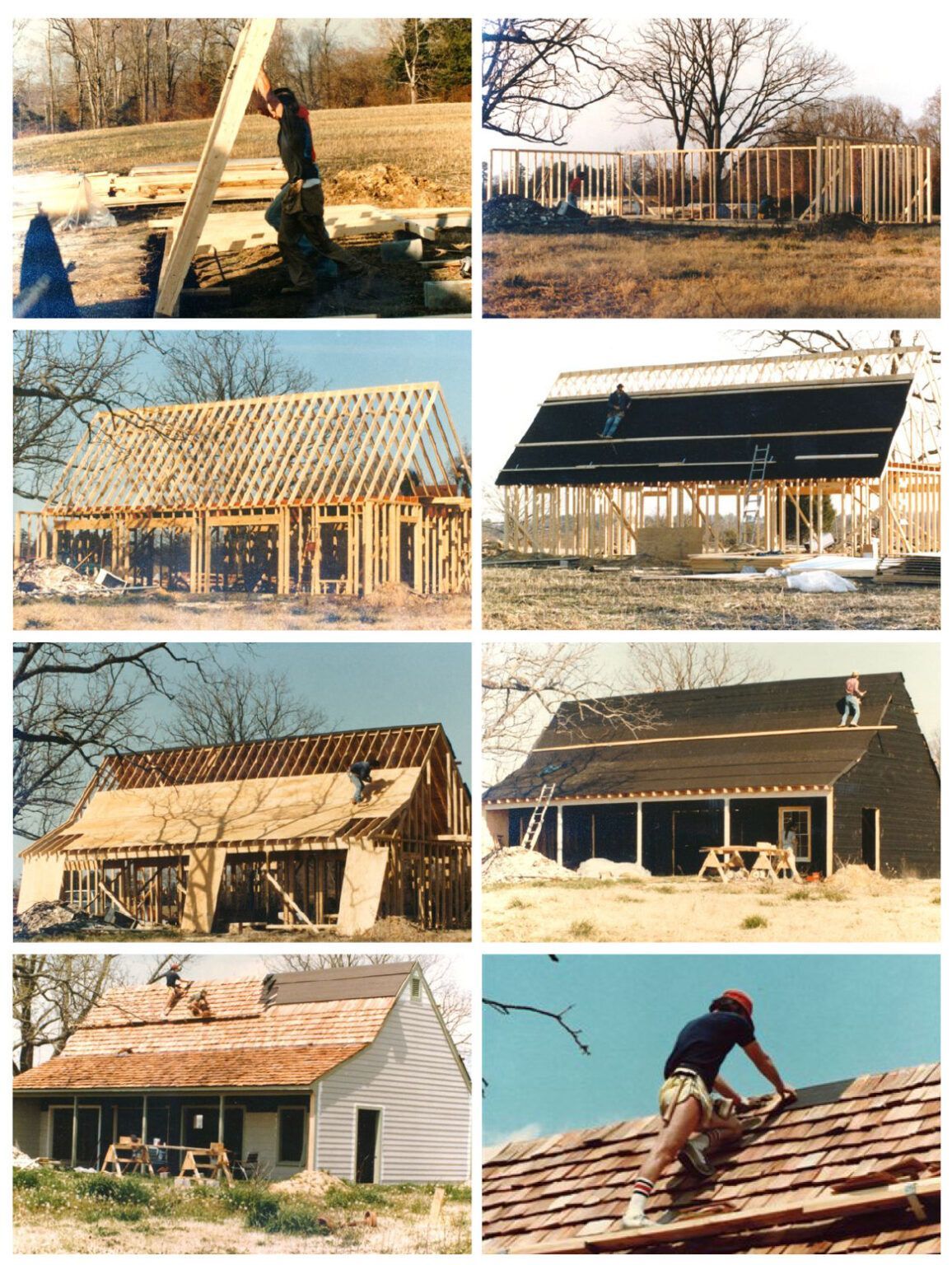

Building the new garage: footing, wall, structure, tar paper to close in cedar shingles, Mike Waltrip and I working on a fast track project.

I have been lucky in life. In the late sixties, working on a farm as a 19 year old, I learned to operate bulldozers, large forklifts, drive ten-wheelers. I made mistakes and have not forgotten them. They were good lessons. My assignment in the seventies to develop the Marlboro World Championship Team and bring the elements together to bring it to world championship success was a thrill. I have also made a fair amount of furniture in very rustic style with hand-carvings.

It may seem almost contradictory but I have all my life been immersed in reading the study and the appreciation of history. After all, that was one of the major factors that attracted me to come back, again and again, and decide to eventually settle in Williamsburg.

The year was 1984 (not the same 1984 that had been described by George Orwell and that got me depressed as a teenager), and the overall plan had been laid out with priorities. Build a garage for the ’72 Mercedes that I was planning to ship in from Europe. A garage large enough to accommodate the Cherokee that we added to the pick up truck and give proper cover to the various furnishings that we had then stacked in old sheds and would eventually find a place in the new house we were designing to be built next to the 1736 house.

I continued commuting to NYC and flying off every month back to Europe. Michael, our talented, artisan carpenter, was steadily working at his pace when I was gone. On weekends I would become a roofer or a plumber as requirements demanded. By late spring we had the garage closed in, siding in place and cedar roofing completed. Next was completion of the West portion of the roof on the old house and we were back in the summer. Pounding nails in the cedars shakes was a job. I was trying to go so fast that Peggy took a couple of pictures so quickly and merged them into one that makes me look like I fooled the camera.

An exciting find in digging the soil for the pour of the concrete floor of the garage were large stones that were identified by an archeologist as ballast stones that had come from England probably in the eighteenth century. Many other artifacts of broken pottery were also found.

The little house looks rejuvenated. Compare it to the picture in Blog/Part 3: Decision Time.

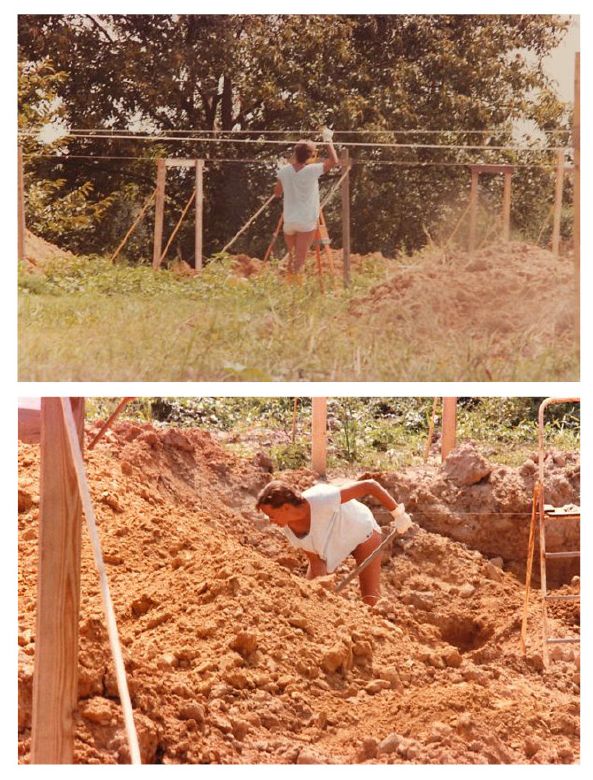

Peggy and I drew the plans for the new house and submitted them to the County for approval. The package quickly came back with a few red lined suggestions for improvements. The concrete footings were poured on September 10 with a large crane to span the spread of the lay-out requiring a diameter of one hundred and sixty four feet. Peggy directed the entire operation with the transit she had acquired to check on the correct level of the various elevations of the concrete pours. I was on a trip and nobody had ever seen such a good looking construction worker.

Peggy organizing batter boards and shoveling up the earth in the trencher before the pour.

We began by building the garage wing of the house and to have it closed and dry as we were concerned about winter and creating adequate storage space to keep construction supplies for the new house.

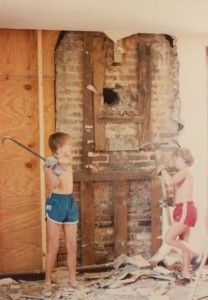

In the meantime, Michael had found a mason and their first task of his team was to attack the fireplace in the old house and bring it back to operational condition. We only knew him as Mr. Hardy and he always addressed me as C’ptain.

As the fireplace had been bricked up, first order was to see how that could be dismantled. I looked closely and noted that some of the bricks were rather loose. So, I carefully scratched the cement surrounding a brick and gently began removing it. The care was intended to prevent the bricked up portion from collapsing on the floor.

As the brick was now in my hand leaving the dark hole, I was stunned to note the eyes of a snake looking at me. I jumped back, asked Patrick and Terence to step out of the room and went to get my gun. The snake had not moved. A single ’22 caliber shot and he was dead. A pretty good size snake. Not a good thing to have him live in the house. (See photo) That was enough excitement for that day. We carefully checked with a flashlight whether there had been other occupants and took down the bricked up part in order to prepare for the rehabbing of the fireplace.

Mr. Hardy and his crew came in the next day and when I told them the story of the snake, they laughed and laughed. Quickly they were working and within a couple of days we had a new fire box and flue and fireplace that would dry up and be ready for winter.

Every Monday morning, I was back on my way to NYC. I had a very narrow focused life while in the big city. The apartment was across the street from the office on 6th Avenue. Early at work with a close knit crew that was expanding as the company was growing rapidly. The evenings were dedicated to study any and all the large volume of material that was available from wine industry sources as well as from studies from accounting firms that had surveyed and/or analyzed the many West Coast wine operations. UC Davis had of course plenty of reading material available.

Preparing for the construction of the fireplace in the old house.

The US industry was (and still is) very different from the French wineries that I hade been involved with or had had the opportunity to examine. The many years of active participation in the French wine world had given me the essence of the industry and the stimulant to open a winery in Virginia. I knew the US wine world was going to be a challenge and I needed to adapt my thinking.

Reading as much as I could, meeting trade people in wine bars which were then relatively new but thriving. Trying to understand consumer patterns, likes and dislikes. Then putting pencil to paper and narrowing issues to the major decisions: what varietal to plant first, where, review again the soil reports, the pH, what pre planting steps to take, what size winery to build, arrange meetings with the VA Tech specialist, follow up with the extension agent over the phone, get all the costing aspects well detailed and begin to build some rough five year projections. Inadequate, make them eight year projections.

But, like the settlers who had arrived some three hundred and fifty years before, once committed, one has to persevere.

(To be continued)

Patrick G. Duffeler

Founder & CEO