Part 10: The First Planting

Let’s do it. Just do it. Demonstrate with deeds, not just plans. We had committed ourselves to the project in 1980, purchased the farm in ’83, and had done a lot of studying. Now, 1985 was the time to get serious. The decision had been made to go ahead and do the first planting of grapes on a nearly three acre size plot on a South facing slope just East of the new house which was under construction.

Specifications:

- Chardonnay varietal with plants sourced from Jochem Hollerith, the winemaker at Prince Michel.

- Rows: 8 feet apart oriented along the slope to minimize run-off. Plants three feet apart.

- Trellising: vertical shoot positioning. Cordon wire at height of 38 inches. Posts: treated wood every 12 feet. Heavy end posts with ground anchors. Additional 4 wires to hold the shoots.

- Plant density: approximately 1,600 plants per acre.

Irrigation: goal was to install a drip irrigation system with underground line and a tube running about 10 inches below the cordon held by another wire and a drip diffuser per plant.

Now we needed the equipment and the supplies. A contact gave us a folder on great agricultural buys, and I noted a 50 HP foreign made diesel tractor at a price of $5K. I had scouted the regional ag equipment distributors and well-known brands were running about twice as expensive for comparable size tractors. Within a week, the tractor arrived. Zetor brand; it was made in Hungary and was rugged. We secured a good bushhog and the auger implement for drilling holes in the soil for the installation of the posts. The wire, the posts, and all the corresponding supplies were ordered and deposits made.

As I was still flying back and forth for my weekly work, Peggy arranged for the plowing of the area and personally did the discing. She quickly became a comfortable and effective tractor operator, in addition to her management of the construction and farm cash flow.

Next was installing small flags to locate the rows. By April, the designated area of ground was ready for the planting. Peggy called me and advised me that the planting was going to be made with a mechanical planter and that Jochem and his crew were coming within a couple of days. The posts had not arrived, and the vendor could not confirm the date of their delivery.

We had no choice. The planting had to go forward. The evening of the planting, she called me at the office in NYC and advised me that all had gone well in just a few hours. We were excited, and we had a nice coverage in the VA Gazette. Now we had to wait for the posts to arrive and watch the plants grow without training sticks to train them. I had done a quick cost analysis and while a number of growers use bamboo, I had opted for PVC pipes as more lasting and stronger and also cost effective.

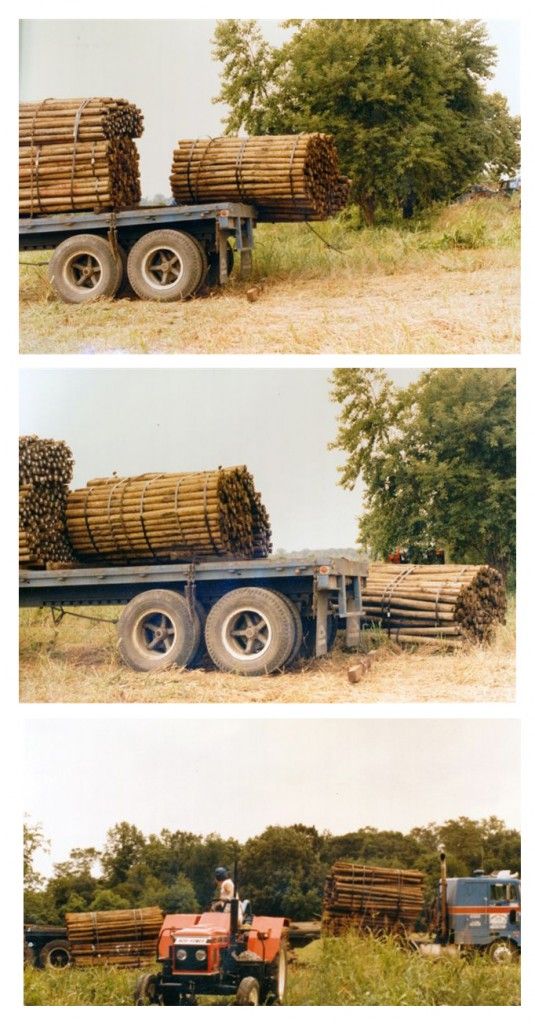

The posts did finally arrive in June on two huge trailers. Unloading the bundles of posts proved there is always another way to skin a cat. Not having a forklift on location, the driver of the truck told me to take a long chain, attach it to the tractor, and pull the bundles straight off the flat bed trailers.

We now had to straddle the growing plants in order to auger the soil between plants to make the holes to install the posts. I had a few days of vacation. Jean-Francois, a seventeen year old nephew who had come to spend a summer with us, had recently arrived from Europe. He was given the task of directing me to ensure that the auger was properly lined up. As we were moving row after row, the augering became more and more difficult and the three point hitch did not seem to have the power to auger as deeply as we needed the holes to be. In the relatively dry spring, facing the South sun, the clay soil had dried up. I asked my nephew to add weight on the three point hitch by standing on the top of the piece lining the auger over the exact place where we were to install the posts as marked by the little flags.

As we felt frustrated by the progressively slowing process, I got off the tractor and examined the auger. Its shape had been burned by the hard gravelly clay and instead of having a good bite by its wing tips as it should, it had literally been chewed up and looked like a dart as opposed to an auger. We rushed over to see our neighbor, Pete Farmer, a uniquely resourceful and talented person who knew how to weld the auger in such a condition that was better than it had been new. He welded special tips to bite into the ground and the next day we were back drilling the holes.

During the following week, while I was back in NY, JF, as we called him, Patrick II, and Terence helped Peggy install the posts in the ground and tamp the soil. Soon the wires were strung and PVC pipes installed such that we could tie the growing vines. The mayflies which were still alive in June, were wicked, and our vineyard crew was unhappy. They still had to learn from the carpenters that coconut sun-tan oil is a great repellent for mayflies.

By August, it looked like a vineyard, but our next challenge was weed control. After my years in upstate NY, Switzerland, France and Spain, our appreciation of the vigor of weeds in Virginia was somewhat deficient. Soon we found ourselves with vines facing heavy competition from the aggressive Johnson grass. We had purchased our spray rig to hook to the back of the tractor, but I did not want to take a chance with spraying any kind of herbicide so close to the young vines.

I remember asking Patrick II and Terence to help me weed the rows on a Sunday in early August. The temperature rose to nearly one hundred and that day, and I noted that my teen-age sons no longer thought that this project was fun. They quit at one point, in plain disgust. I, stubbornly, kept ripping the rhizomes of the Johnson grass in order to give the vines a chance. It was a long, hot Sunday.

The vines grew and grapes developed. We could see the vineyard evolving from the future master bedroom window in the house under construction.

It was a real milestone.

(To be continued)

Patrick G. Duffeler

Founder & CEO